Team 36 - Volvo

Project Abstract

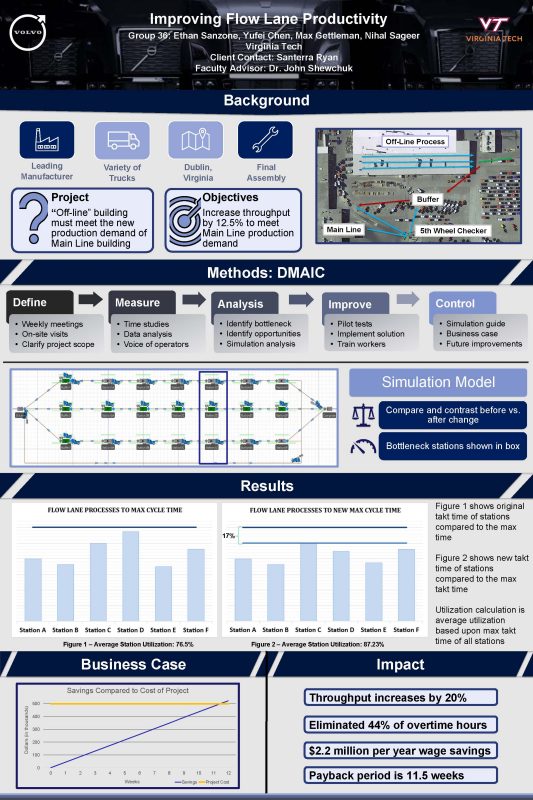

Volvo Group is one of North America’s largest manufacturers of commercial trucks. At their New River Valley Plant, trucks are assembled, tested, and sent to customers. The facility consists of a “main line” for assembly and an “off-line” building for final inspections. Volvo wanted to increase the throughput of the off-line processes by 12.5%, to match the throughput capabilities of the main line. Due to time constraints and truck re-runs caused by errors in production, Volvo struggled to achieve this goal. The team was tasked with finding ways for Volvo to increase its throughput in this building. Using simulation modeling, the team analyzed current inefficiencies, identified system bottlenecks, tested alternative sequencing strategies, and evaluated process modifications. Simulation results were verified and validated with real-world data to ensure accuracy. By iteratively adjusting variables and repositioning station elements within the off-line process area, the recommendations tested in the simulation were able to streamline operations. Given the results from the simulation model, the team was able to achieve the desired throughput increase of 12.5%, with a confidence of 95%. The increased throughput of the off-line building allows for more trucks to be produced in a day while decreasing the number of trucks waiting between the main line and off-line buildings. These improvements in throughput translate to reduced production delays and cost savings for Volvo.

Team Members

Yufei Chen; Max Gettleman; Nihal Sageer; Ethan Sanzone

Client Contact

Santerra Ryan

Advisor

Dr. John Shewchuk